A plant with a global presence

Tobacco is the core component of our products. The three tobacco types are Virginia, burley and oriental. These tobaccos are grown in over 30 countries including Argentina, Brazil, China, Greece, Italy, Malawi, Mozambique, Spain, Tanzania, Turkey, and the United States.

- Virginia, or flue-cured tobacco, is also known as 'bright tobacco' because of the golden-yellow to deep-orange color it takes on during curing. Typically cured for a week in heated barns, it has a light, bright aroma and taste. Virginia tobacco is mainly grown in Argentina, Brazil, China, India, Tanzania, and the United States.

- Burley tobacco is light to dark brown in color. Air-cured in barns for up to two months, burley loses most of its natural sugars and develops a strong, almost cigar-like taste. It is mainly grown in Argentina, Brazil, Italy, Malawi, and the United States.

- Oriental tobacco is highly aromatic. Its small leaves are harvested individually and sun-cured in the open air. It is mainly grown in Bulgaria, Greece, Macedonia, and Turkey.

From these tobacco types come the two distinctive blends that make up much of the world's cigarette market:

- Blended cigarettes typically use the three main tobacco types: Virginia, burley, and oriental. Ingredients are often added to replace the sugars lost during curing and provide the distinctive flavor and aroma of each cigarette brand. Blended cigarettes dominate the United States, most of Europe, Latin America, Eastern Europe, and many Asian markets. Popular blended brands include the Philip Morris International brands Marlboro, L&M, and Chesterfield.

- Virginia cigarettes are mostly made of Virginia tobacco. Virginia-style cigarettes are popular in the U.K. and former British colonies including Australia, Canada, India, Malaysia, Nigeria, Pakistan, and South Africa. Virginia brands are particularly popular in China, the world's largest cigarette market. Popular Virginia-blend brands include PMI’s Longbeach, Peter Jackson in Australia, Canadian Classics, and Number 7 in Canada.

Other cigarette types include those made from dark or air-cured tobaccos, oriental-tobacco cigarettes, and kreteks, which contain cloves and are popular in Indonesia.

Learn more about the art of blending by watching this video:

The art of selecting and blending tobacco explained

Music starts

The words Inside PMI appear on screen.

Follow the journey from seed to shelf and discover how we make and market our products at PMI.

Part 1: Tobacco blending

Voiceover begins: I’ve got the best job in the world.

I think I work with really passionate people who really care about what they do.

There’s a common bond because there’s so much work and passion that goes into growing this crop.

I started my career in tobacco in Turkey....

The words: Tony Snyder, Vice President Product Development is seen on screen.

Voiceover continues: ... so for me the oriental tobacco will always be a favorite.

It has an aroma and a flavor which is so intense.

It all starts with the tobacco, the defining element of each of our products.

What's important for the tobacco is a combination of things, what varieties of tobacco are used, where it comes from, the weather conditions and the soil in which it’s grown.

But most importantly it’s the farmer.

Because the farmer can make the difference between a good quality crop and a bad quality crop.

We don’t actually own our own farms but we work very closely with contracted farmers in some countries and with major tobacco suppliers in most of the other markets in which we procure tobacco from.

The first thing, when I want to understand what a tobacco is going to taste like, is the smell.

And the smell tells the whole story. It gives a sense of depth, how much character it has and you can tell how it’s gonna taste.

The blender has to do two things.

One, ensure we have consistent quality from year to year, in spite of any changes in the crop.

The second, is to develop the new products which are going to hit the right notes on taste.

So you can’t go to college and learn how to be a blender. That only comes with years of experience.

We’re building up a memory of the taste of each different type of tobacco so you have this inventory in your mind.

It’s good, it’s got a very delicate flavor, much more so than you usually expect from Brazil.

We have to use all the tobaccos available to us to make a harmonious balanced product.

The trick for the blender is to make sure they can do something that doesn’t overplay the richness, that isn’t too bland, that hits the sweet spot which has complexity and that harmonious taste, day in, day out, year in, year out.

Music stops

The words visit www.pmi.com appears on screen.

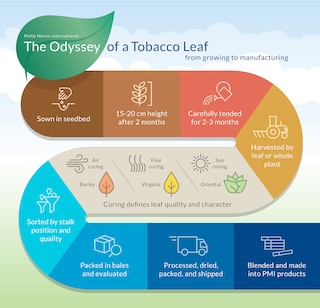

The odyssey of a tobacco leaf

Tobacco begins its lifecycle as a seed sown in a specially constructed seedbed. After two months, the seed has grown into a plant some 15-20 cm high, strong enough to continue its growth in the field for the next two to three months, carefully tended to maximize yield and quality.

Tobacco is harvested either leaf by leaf, in the case of Virginia and oriental tobaccos, or by the whole plant, in the case of burley.

The next stage, curing, plays a major role in defining the leaf's final quality and character. Each tobacco type is cured differently: air-curing for burley, flue-curing for Virginia, and sun-curing for oriental.

Leaves are next sorted by stalk position and quality, then packed in bales, which are evaluated by leaf buyers.

Tobacco leaf completes its journey through final processing which, for burley and Virginia tobaccos, includes separation of leaf from stem and removal of sand and nontobacco materials. The tobacco is dried, packed in cases, and shipped to our manufacturing centers around the world where it is blended and made into cigarettes.

Tobacco growing

The growing process for tobacco has not changed much in the last 200 years. Technology has been added, of course, to make production more efficient, but the different stages of the process remain more or less the same.

We source high-quality tobacco from leaf suppliers and farmers in over 30 countries. We require that our suppliers follow our Good Agricultural Practices (GAP) program, which cover the entire tobacco growing process: planning the crops, selecting the right site with appropriate soil type and fertility, and preparing the land to ensure the tobacco we buy has the very best foundations on which to grow.

Crop cultivation

In the first stage of the growing process, tobacco seeds are sown in specially-constructed seedbeds. Selecting the right tobacco seed variety is essential to achieving a good yield of the desired quality of tobacco leaf. The seeds are sown in seedbeds (not too close together) to give each seedling enough room to grow.

Tobacco seeds are tiny – there are between 10,000 and 13,000 of them in a gram – and they germinate rapidly in five to ten days. Under the ideal seedbed conditions, they will grow to a height of 15-20 centimeters in about two months. They are then transplanted in the fields.

Harvesting

After two to three months, the plants are ready for harvesting. It is important to harvest precisely when the leaves are mature (or ripe) and in prime condition for curing.

Tobacco plants ripen from the bottom to the top. The farmers start harvesting Virginia tobacco by picking the early ripening leaves closest to the ground. They then move up the plant, picking the stalk layers as they ripen. Only three to six leaves are removed from the plant at each harvesting stage. Burley tobacco is normally harvested in a different way: farmers cut the whole plant and remove the leaves from the stalk after curing. Oriental tobacco leaves are harvested by hand, one by one, off of the plant as they ripen.

Tobacco curing

The curing of tobacco plays a major role in the final leaf quality, and it must be carefully controlled in order to bring out the characteristic taste of each tobacco type. Different types of curing are used for different types of tobacco.

Virginia tobacco is 'flue-cured.' The tobacco leaves are hung in curing barns, where heated air is generated to dry the leaves. As the leaves lose moisture, they develop their distinct aroma, texture, and color. The farmer must carefully guide this process, which takes up to a week, during which time the temperature of the heated air must be constantly monitored and gradually increased. Too much or too little heat at any stage of the process will have a negative impact on the quality of the tobacco.

Burley and oriental tobaccos are cured differently. Burley is 'air-cured' in barns where the heat and humidity come from natural ventilation. The curing process takes up to two months. Oriental tobacco is 'sun-cured' by hanging the leaves outdoors in the sun for about two weeks.

Grading and stabilizing

When the leaves have been cured, the tobacco farmer sorts them according to stalk position and quality, and packs them separately into bales for delivery to the point of sale. At the point of sale, the leaves are graded by expert leaf buyers who assess leaf quality by carefully checking variations in color, texture, and aroma.

Once the tobacco has been purchased, it is shipped to a local processing factory where the leaves are further processed and dried for uniformity. After the drying process, the tobacco is pressed into cases for shipment around the world.

Tobacco leaf may be stored for several years. The aging process helps to improve the flavor. After aging, the tobacco is moved to one of our manufacturing centers around the world, where it becomes part of the blends we use to manufacture our products.