Impact of COVID-19 on our activities in 2020

Overview of our 2020 carbon footprint

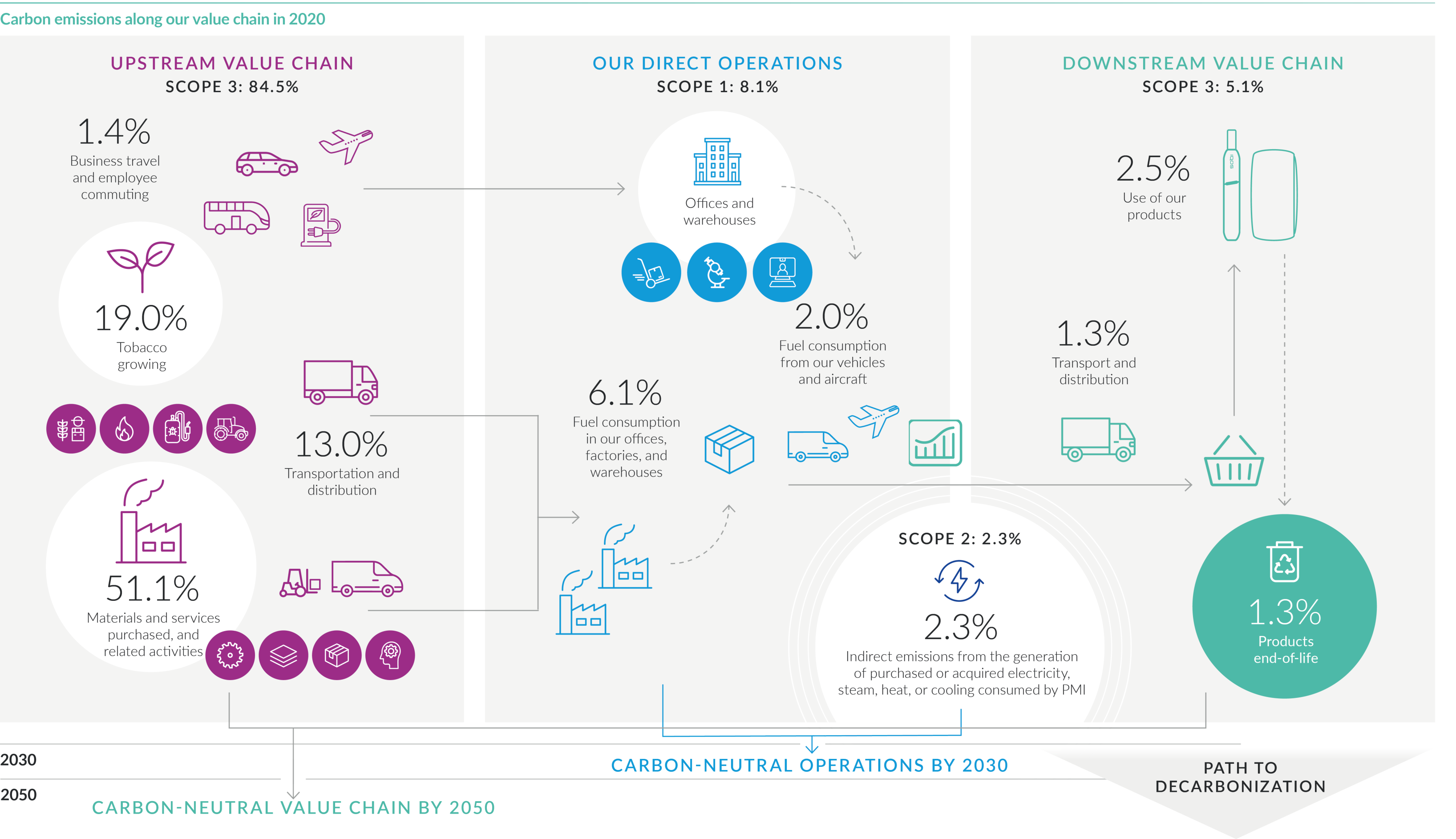

Accurate measurement and transparent reporting of our footprint enables us to shape our strategy, set targets, and measure progress. We calculate our GHG footprint annually, following guidance from the Greenhouse Gas Protocol and accounting for all emissions generated across our value chain.

The emissions generated by our direct operations—including our factories, offices, and fleet—are a key focus, but they amount to around 10 percent of our total GHG footprint. One critical producer of GHG emissions we seek to address is the energy required to produce the consumables for our smoke-free products, which is approximately four times greater than for cigarettes. This is mainly due to the additional steam required in the manufacturing process. This leads to an increase in GHG emissions, which we address with multiple energy-saving measures.

Representing 85 percent of our total GHG footprint, our upstream emissions include those generated by curing fuels and fertilizers in our tobacco supply chain, acquiring and transporting direct materials such as paper and cellulose acetate tow, procuring indirect materials and services such as marketing, sales, and other professional services, third-party disposal and treatment of waste, and business travel and employee commuting.

In this chapter

- Impact of Covid-19

- Overview of our carbon footprint

- A new approach to carbon pricing at PMI

- Decarbonizing our operations

- Driving carbon reduction in our tobacco supply chain

- Climate protection in our direct materials supply chain

- Next steps

Downstream, emissions generated by the transport and distribution, use, and end-of-life management of our products represent 5 percent of our total footprint. The emissions related to use and end-of-life management of our products are slowly but steadily decreasing mainly due to improvements in our heated tobacco units as well as the devices design that impact its use and end-of-life emissions. Eco-design principles inform how we use life-cycle analysis (LCA) to assess the carbon footprint of our products, from tobacco sourcing to end-of-life impacts.

Overall, in 2020 our emissions decreased in absolute terms by 18 percent across our value chain versus 2019, amounting to a reduction of 862,699 tons of CO2e. More specifically, we achieved a year-on-year absolute reduction in scope 1 emissions of 19 percent, in scope 2 of 43 percent, and in scope 3 of 17 percent.

A new approach to carbon pricing at PMI

An increasing number of organizations and sustainability leaders are using internal carbon pricing to structurally drive a reduction in CO2 emissions. Assigning a price—and hence a theoretical cost—to the emissions generated makes an intangible more concrete and further incentivizes actions to reduce the emissions contributing to global warming.

In 2020, we took a new approach to internal carbon pricing at PMI, developing two complementary internal carbon prices: A shadow price and a carbon levy.

- A shadow price of USD 65 per ton of CO2e:

Our shadow price is an internal lever designed to accelerate carbon emissions reduction by ensuring that the company’s investment decisions reflect all costs, including environmental ones. We use this price to better understand the potential impact of external carbon pricing (e.g., carbon taxes) on the profitability of a project, a new business model, or an investment, and hence drive and prioritize investments that accelerate CO2 emissions reduction to a level that is considered as unavoidable (i.e., technically or economically not further abatable). We modeled what an adequate shadow price should be for PMI following a robust methodology, best international practices (such as guidance from the World Bank and the Stiglitz and Stern price corridor concept), a worst-case scenario analysis of transition risks projected by 2040, and specificities of our emission profile and geographic footprint. PMI’s shadow carbon price is integrated into the financial evaluation and preparation of business cases that will impact our carbon emissions (favorably or unfavorably); in 2020, it was instrumental in the approval of 13 additional carbon emission reduction projects as part of our energy saving initiatives program in our manufacturing sites.

- A carbon levy of USD 8 per ton of CO2e:

The carbon levy internalizes external costs and supports behavioral change. It is an internal tax that is virtually charged to selected business units for their emissions, with the aim to use the calculated virtual revenue to size and fund investments that contribute to the decarbonization of the business. While the shadow price helps in the prioritization of business cases for investment in activities aimed at structurally reducing our carbon emissions, the carbon levy helps size the investments required today to abate our emissions through offsetting (e.g., acquisition of green certificates) or in-setting initiatives (e.g., agroforestry projects, carbon sequestration programs). We have modeled what the carbon levy should be for PMI basing our calculation on data on the forecasted voluntary carbon market prices, our CO2 compensation profile (i.e., the number of tons of CO2 to be compensated through offsetting/in-setting investments), our carbon neutrality time horizon, and the compensation strategy we want to adopt. We started implementing our carbon levy in 2020 within the business functions accounting for the bulk of our direct emissions, such as our manufacturing sites, offices, and fleet, to form a budget that will be conducive to setup a portfolio of climate investments to compensate remaining unavoidable CO2 emissions and achieve carbon neutrality.

We will revise our shadow price and carbon levy annually to allow the integration of changes in our risk or emissions profiles.

How we calculate HGH emissions

Decarbonizing our operations

Our sites and fleet are the parts of our value chain over which we have the greatest control. We have committed to becoming carbon neutral in our direct operations by 2030, and this commitment applies to our manufacturing facilities, our offices and warehouses, and our fleet. To achieve our ambition, we combine good management practices with strategic energy-related investments across our operations. We invest in optimizing energy and process efficiencies and replacing fossil fuel-based energy with renewable sources. We compensate our absolute carbon emissions only as a last resort—once we have maximized our emissions reduction via energy efficiencies and renewable energy. Our aim is to compensate unavoidable emissions via credits generated through in-setting projects, including nature-based solutions and other carbon removal technologies. Based on our new carbon levy, we are setting up a portfolio of climate investments (resulting in carbon credits generation or acquisition) for carbon compensation.

Our factories

A key component of the program is encouraging behavioral change and an ownership mentality. To reduce carbon emissions in our manufacturing sites, we promote efficient energy use through our Drive 4 Zero program, which establishes a common way of working across our factories. To promote a zero-loss mindset, we designed our systems to facilitate new ideas aimed at eliminating process losses (e.g., energy, materials, water). This seeks to empower every worker to look for losses and recommend and implement solutions. We apply improvements not only across the factories but also throughout the company.

Through this program, we implemented energy-saving projects across all our factories in 2020. Throughout the year, the program triggered more than 140 projects worldwide, ranging from chilled water optimization, heat-recovery projects, and LED lighting to heating, ventilation, and air conditioning system upgrades. Overall, our efficiency initiatives helped drive around 10 percent reduction in carbon emissions across our manufacturing facilities in 2020 versus 2019.

In parallel to our efforts to drive energy efficiency, we focus on switching to renewable energy sources. We implement technologies to generate renewable energy across our manufacturing sites, such as photovoltaic panels, biomass boilers and heat pumps, and tri-generation processes (combining cooling, heat, and power). For instance, in 2020 we installed pyrolysis technology in our factory in Neuchâtel, which uses operational waste instead of fossil energies to produce steam and hot water. It will be operational in 2021, and we will communicate results in our next report. This factory became our second carbon-neutral facility, receiving certification from the Swiss non-profit organization myclimate. As another example, in 2020 our photovoltaic installation at our Bologna factory in Italy reached its full capacity, generating around 4 percent of the total energy used on the site in a year. In 2020, 34 percent of our total energy consumption came from renewable sources.

We are also on track to achieve our target of 100 percent electricity used in our factories to be from renewable sources by 2025. In total, 78 percent of the electricity used in our manufacturing facilities in 2020 came from renewable sources.

Overall, our efforts led to a reduction of 89,112 tons of CO2e in our manufacturing facilities in 2020 versus the previous year, with the increased energy required to produce smoke-free products offset by our efficiency efforts and our switch to renewable energy.

Our fleet

In 2020, our fleet of around 23,000 vehicles covered around 370 million kilometers. Our fleet comprises working tool cars (75 percent) and benefit cars (25 percent).

During the year, we developed a carbon-neutrality strategy for our fleet, along with supporting targets, and built organizational capability within the company.

From an environmental perspective, the first focus for our fleet is to optimize fuel consumption and improve operational efficiency. We do so through eco-driving training and the use of telematics. In 2020, we established a dedicated fleet safety e-learning platform with eco-driving modules. We started rolling it out early 2021, and we intend to reach a participation rate of over 70 percent in 2021. Telematics were installed in 35 percent of our vehicles by the end of 2020. This technology provides the driver and the company with data on driving behaviors and helps improve road safety, reduces occurrence of fatalities and injuries, and—as an outcome—leads to a decrease in carbon emissions. We aim to equip 75 percent of our total fleet (i.e., all working tools cars) with such technology by the end of 2023.

As an important step toward the reduction of our carbon emissions, we are also making changes to our fleet of cars and vehicles, minimizing the use of combustible fossil fuels and switching to alternative eco-powertrains—such as hybrid and electric vehicles. This shift has already begun, with green vehicles representing 4.7 percent of our fleet in 2020, but we plan to further accelerate it following the introduction of our global Fleet Policy in January 2021.

We estimate that our efforts translated into more than 2 percent GHG emissions reduction in 2020 versus 2019 in our fleet. Additionally, due to less mileage (COVID-19 impact) GHG emissions were reduced by more than 20 percent.

Our offices

We have offices and warehouses in over 80 markets worldwide, most of which we lease rather than own. In 2020, we focused on gaining visibility into energy use at those sites and preparing action plans to optimize energy consumption and promote the switch to renewable sources. In 2021, we will pilot these action plans in markets identified as the biggest contributors to our carbon footprint. Those include Indonesia, the Philippines, Poland, Russia, and Singapore.

In 2020, with 28,161 tons of CO2e produced our offices and warehouses represented 7 percent of our carbon emissions in our direct operations (scope 1 and 2), but only 0.7 percent of our total carbon footprint. Our offices in Switzerland were again certified carbon neutral and we purchased 100 percent green electricity in our offices in Portugal, New Zealand, and Sweden, as well as in our tobacco warehouse in Greece.

Driving carbon reduction in our tobacco supply chain

Our tobacco supply chain represented 23 percent of our total carbon footprint in 2020. It amounted to a total of 911,160 tons of CO2e, a decrease of 28 percent versus 2019. This significant reduction was driven largely by our efforts to tackle our main source of carbon emissions—the process of curing tobacco—but also due to a gradual decrease in our overall tobacco demand.

Now that we have achieved significant progress in reducing GHG emissions from tobacco curing, we are exploring other contributors to our footprint, such as the use of fertilizers and mechanization. We are already exploring opportunities on the reduction of emissions through technological innovations that are rapidly becoming more available in farming. In parallel to our reduction strategy, we are assessing nature-based solutions, which present an important opportunity due to the high potential for carbon removal and the linkages with our tobacco operations both on the farm and next to the farm at landscape level.

In line with PMI’s carbon-neutrality ambitions, we developed new targets for our tobacco supply chain: We aim to achieve an absolute carbon emissions reduction of 35 percent by 2025 and of 50 percent by 2030 versus the 2019 baseline. We will continue our efforts to decarbonize tobacco curing while implementing additional reduction initiatives focused on the use of fertilizer and mechanization.

Tobacco curing

We mainly source three types of tobacco: Virginia, Burley, and Oriental. Virginia tobacco (approximately 47 percent of our purchased volume) is cultivated around the world and, once harvested, is generally cured by using an external heat source to dry out the leaves—a process called “flue-curing.” Curing barns may be heated with coal, diesel, natural gas, firewood, or biofuels containing agricultural and wood-sawing by-products. The GHG emissions of flue-cured tobacco represent 6 percent of our total carbon footprint and over a quarter of the total GHG emissions related to our tobacco supply chain.

Our Monitoring and Verification Framework for Sustainable Leaf Curing Fuels allows us to systematically monitor the sustainability of all fuel types used in our tobacco supply chain. We apply it in all flue-cured sourcing markets to verify results on the ground and foster improvement. During 2020, we completed 23 audits—performed remotely due to the COVID-19 pandemic—covering all flue-cured origins to verify carbon reduction activities and data on fuel use per kilogram of tobacco cured.

In 2020, we achieved a 77 percent reduction in GHG emissions per kilogram of flue-cured tobacco versus our 2010 baseline, exceeding our target of 70 percent. One-third of this decrease was driven by efforts to make curing barns more efficient, while the remaining two-thirds resulted from the switch to renewable fuels.

We have set new targets related to decarbonizing the tobacco curing process, which will guide our efforts in the years to come. By 2025, we aim for a 75 percent reduction in emissions generated by curing one kilogram of tobacco, against our 2019 baseline. We will focus on increasing the use of renewable fuels in markets that still use a mix that includes fossil fuels.

Curing barns efficiency

A primary reason for the low energy efficiency of tobacco curing barns is the lack of insulation and the thermal conductivity of the construction materials. As most farmers own their curing barns, we collaborate with our suppliers to provide guidance and support to make the barns more thermal-efficient. Typically, our efforts aim to improve combustion efficiency, ventilation, and heating control, together with insulation. While delivering improvement projects worldwide, it is important also to train farmers on fuel efficiency, barn maintenance, and fuel sustainability.

The improvement projects we carried out in 2020 increased the efficiency of 2,146 barns in China, Malawi, the Philippines, Pakistan, and Brazil for a cumulative total of around 82,500 barns upgraded since 2014 and covering farmers in more than 10 countries. The reduction of carbon emissions in the curing process have also benefited from the increased efficiency of the barns that have been improved year on year with interventions mostly related to the thermal cycle and the insulation of the barn structures against fugitive heat.

Renewable fuels

To reduce GHG emissions, we are gradually phasing out fossil fuels such as coal and diesel in favor of renewable fuels. In 2020, 67 percent of the flue-cured tobacco we purchased was cured with renewable fuels, mainly sustainable firewood, but also biomass, such as wood sources, agro-pellets, and other agricultural waste products. We aim for 70 percent of our purchased flue-cured tobacco to be cured with renewables by 2021.

Sustainable firewood

Protecting natural ecosystems and sustainably managing forests, which are important carbon sinks, are key drivers in reducing greenhouse gas emissions. Critical to our work on curing fuels is ensuring that the firewood and other wood-based materials used to cure the tobacco we purchase do not contribute to deforestation. We are committed to sourcing wood fuels from traceable, sustainable, and legal sources and have set targets for our tobacco supply chain as part of our Zero Deforestation Manifesto.

Our Monitoring and Verification Framework for Sustainable Leaf Curing Fuels enables us to assess the risk of deforestation represented by different wood fuels, collect sourcing information on the wood fuels farmers use to cure tobacco, and confirm that those sources do not contribute to deforestation. In 2020, we achieved our target of having 100 percent of the tobacco we purchase cured with no risk of deforestation of old-growth forests (i.e., primary and protected forests).

Eliminating coal

Eliminating coal by switching to renewable fuels, which implies the conversion of curing infrastructures, remains a priority for us. We had set a target to phase out coal completely by the end of 2020 and had made steady progress in switching to more sustainable fuels across our sourcing countries. However, shifts in our sourcing strategy and local curing capacities in certain regions resulted in 11 percent of the flue-cured tobacco we purchased in 2020 being still cured with coal (down from 16 percent in 2019).

This pertained to tobacco purchased from the Yunnan and Guizhou provinces of China, where the prevailing curing fuel used by tobacco farmers is coal due to its competitive price and availability.

In 2016, we embarked on a multistakeholder initiative led by the China National Tobacco Corporation and supported by local governments aimed at converting curing barns from coal to biomass and creating a fuel pellets supply chain produced from agricultural waste. By the end of 2020, more than 71,000 curing barns had phased out coal and converted to biomass, leading to a significant reduction in GHG emissions from tobacco curing (from 4.62 to 2.84 kg per kilo of cured tobacco), measured and verified through our Monitoring and Verification Framework. Beyond the carbon reduction achieved by the barn conversions, the project increased farmers’ incomes, as commercial tobacco grades were lifted between 8.6 percent and 11.8 percent for the farmers who switched to biomass-based curing. More detail on this project is available in a case study we published with the World Business Council for Sustainable Development in 2020. Biomass pellet auto-feeder attached to the burner has reduced by half the requirements in hours of labor for fuel loading and ash cleaning, lowering the overall cost of production. The estimated cost saving in labor equates close to USD 43 per farmer per season. Coupled with an average price increase of USD 0.17 per kilogram of tobacco driven by quality improvement compared with coal curing, we estimate an average additional income of USD 357 per farmer and per season from tobacco sales.

We remain committed to eliminating coal from our curing fuel portfolio and expect to phase out coal completely by 2023.

Fertilizers

The use of fertilizers in tobacco production represented around 8 percent of PMI’s total carbon footprint in 2020, making it the second largest contributor of GHG emissions upstream in our supply chain, after acetate tow. While we encourage the optimization of fertilizers—minimizing their use in line with our Good Agricultural Practices—the adoption of carbon abatement technologies in the manufacturing of fertilizers has also contributed to reducing their CO2 footprint.

In 2019, PMI updated its calculation model for the CO2 emissions of fertilizers. In 2020, we refine the calculations to more precisely assess their impact on the company’s carbon footprint using more accurate primary inputs on production yield against fertilizer application rate. We focused on understanding the geographic origin (i.e., production plant location) of the nitrogen component of some fertilizers to assign them a more precise emissions factor. By taking into consideration efficiency gains and technological developments occurring in the manufacturing of fertilizers, the total emissions calculated for 2020 are more accurate. While emissions represented an increased share of PMI’s total carbon footprint in 2020, they were 11 percent lower in absolute terms than in 2019. The next step in developing the model will be aimed at understanding the impact on emissions of different types of application method of nitrogen-based fertilizers. In 2020, we focused our efforts on improving productivity versus inputs, through the constant implementation of our GAP program and some specific projects linked to better use of inputs. For instance, in Argentina we started together with our farmers to switch irrigation technology to drip in order to both save water and reduce the application of fertilizer per hectare.

In-setting and nature-based solutions

In 2020, we developed a targeted study to map the potential of nature-based solutions (NBS) in our tobacco supply chain and evaluate natural carbon sinks in the context of our carbon neutrality ambition. The focus has been on testing multiple methodologies in three markets (Brazil, Mozambique, and the Philippines) where we believe opportunities are significant and investments could yield the best return in carbon removals generated. The methodologies that we selected are internationally recognized and aligned with the strategy of promoting more resilient forests and sustainable agriculture. We applied reforestation, afforestation, and adoption of sustainable agricultural land management methodological approaches. The study was useful to define the lines of intervention and the scale we will be adopting for future NBS projects in our supply chain. We plan to pilot NBS on the ground by developing one project in 2021, leveraging on the experience that we have acquired this year.

In our last report, we communicated on plans related to an in-setting project related to provision of clean and safe drinking water to farmers within the tobacco-growing areas of Mozambique. The development of the in-setting project has been postponed for a year, given challenges brought by the COVID-19 pandemic. We are actively working on its implementation in 2021 with Carbonsink and we will report on progress next year.

Climate protection in our direct materials supply chain

Beyond tobacco, the materials and services we purchased represented 45 percent of our total GHG footprint in 2020. Of this, 66 percent originated from the direct materials we source, such as cellulose acetate tow, pulp and paper, and our smoke-free electronic devices.

Engagement with our suppliers is instrumental in driving carbon reduction efforts. We accomplish this in a variety of ways. For instance, we organized two webinars in 2020 involving over 50 suppliers across our supply chain categories. The webinars reaffirmed PMI’s carbon neutrality commitments and explained our strategies while also training participants on CDP disclosure. In recognition of our efforts, CDP placed PMI on its Supplier Engagement Leaderboard in 2020 for the fourth consecutive year for our actions and strategies to reduce emissions and lower climate-related risks in our supply chain.

Within our supply chain, the direct materials used in the manufacturing of our products—cellulose acetate tow, pulp, and paper (packaging board)—have the greatest impact on our footprint. During the year, we developed and launched a new and comprehensive Supplier Engagement program with our suppliers to collect primary carbon data and understand their GHG emission reduction programs and targets. In 2020, we engaged with 41 suppliers across our direct materials category, representing 80 percent of the category’s total carbon footprint. This engagement and the data collected allowed us to significantly improve the accuracy level of the associated carbon emissions calculation, drive the future engagement strategy, and develop a comprehensive roadmap to accelerate the decarbonization of our supply chain. In our engagements with suppliers, we also emphasized our Zero Deforestation Manifesto as a critical driver in tackling climate change.

In 2020, emissions from our non-tobacco direct materials supply chain amounted to 1,182,445 tons of CO2e, a decrease of 14 percent versus 2019.

An organization’s upstream emissions are typically more than 10 times greater than their direct operations. Therefore, we must replicate and champion our own sustainability efforts with suppliers by working together on solutions and programs that have the greatest impact in reducing our environmental footprint. This year’s recognition from CDP further reinforces our commitment to transparently report on our progress as we work toward tackling climate change and accelerating our sustainability efforts.Laurence Ruffieux PMI Director of Operations Sustainability

Performance highlights

Next steps

In 2021, we will roll out our new internal carbon pricing to help drive PMI’s transition to a low-carbon operating scheme. We will further accelerate the decarbonization of our fleet and offices, deploying the strategies developed in 2020.

In our factories, we will continue to implement energy efficiency and conservation initiatives, increase the share of renewables, switch to green electricity, and promote efficient energy use through our Drive 4 Zero program. We plan to certify additional sites as carbon-neutral by the end of 2021 and aim to develop a roadmap to certify the majority of our factories—that will be representing around 80 percent of PMI’s estimated total production—by 2025. In the medium term, we aim for a gradual shift from improved process technologies to more disruptive technologies such as carbon removal technologies.

In our fleet, we will roll out our new Global Fleet policy, accelerating the transition to electric and hybrid cars and equipping our vehicles with new technologies to drive efficiency. As regards our offices and warehouses, we will start rolling out our strategy in our top 10 contributing markets. Best practices we will gather related to facility management (e.g., lighting and temperature efficiency, renewable energy sources, and purchase of green energy) will be recorded and used for further reapplication across other markets.

In our tobacco supply chain, we will focus on our newly set targets and further reduce absolute emissions through continuous improvement in curing fuels and additional emissions-reduction initiatives for fertilizers and mechanization. Building on the major progress we have achieved over the past several years, we are now exploring natural climate solutions, working with our contracted farmers on actively managing and restoring soils and growing more trees, which will naturally remove CO2 from the atmosphere if properly preserved. In 2020, we conducted a preliminary study to assess the potential of nature-based solutions in three markets and, in 2021, we will develop our first pilot project on the methodologies we have tested. The contribution of removal projects will be reported separately from the reductions.

In our non-tobacco supply chain, we plan to extend our supplier engagement and data collection efforts in 2021 to cover additional product categories. We are also exploring the use of a digital platform to facilitate our carbon data management and amplify our supplier-focused activities. Moreover, we plan to evaluate the inclusion of reduction commitments in our business volume allocation criteria and carbon pricing as part of the tender process.

Encouraged by our progress, recent achievements, external recognition by CDP’s Triple A, and the validation of our new targets by the SBTi, we are confident we can achieve our carbon neutrality target in our operations (scope 1 and 2) before 2030. During 2021, we will work on developing a plan to significantly accelerate our efforts and communicate on it accordingly.

We also plan to reassess climate change risks and opportunities in line with a 1.5 degrees Celsius scenario in 2022.

PMI wants to remain at the forefront of the climate neutral agenda. We believe investments and bold strategies will be key, and conditions today are optimal to accelerate decarbonization strategies and projects, and to reduce the overall company’s footprint and improve our supply chain resiliency in managing climate-related risks and seizing opportunities in the low-carbon economy.

This online content about our Integrated Report should be read in conjunction with PMI’s 2020 Integrated Report. The information and data presented here cover the 2020 calendar year or reflect status at December 31, 2020, worldwide, unless otherwise indicated. Where not specified, data come from PMI estimates. Please also refer to 'About this report' on page 3 of the 2020 Integrated Report for more information. Aspirational targets and goals do not constitute financial projections, and achievement of future results is subject to risks, uncertainties and inaccurate assumptions, as outlined in our forward-looking and cautionary statements on page 145. In the 2020 Integrated Report and in related communications, the terms “materiality,” “material,” and similar terms, when used in the context of economic, environmental, and social topics, are defined in the referenced sustainability standards and are not meant to correspond to the concept of materiality under the U.S. securities laws and/or disclosures required by the U.S. Securities and Exchange Commission.