| INTEGRATED REPORT 2019 |

There is a need to change economic models of production and use, moving to a more restorative model. Building sustainability considerations into product design is a way to control environmental and social impacts across the life cycle of a product – from development and manufacture to use and disposal.

Why it is important to us and our stakeholders

By integrating sustainability considerations into our products, from development to end-of-use, we can lower their environmental and social impacts and costs. Potential benefits include energy savings, reduced use of natural resources, waste reduction, and, typically, a longer product lifespan. Minimizing the negative environmental and social impacts of products commercialized at scale can help safeguard the interests of future generations.

At PMI, we are committed to playing our part in promoting a circular economy. Our stakeholders, starting with our consumers, expect products that are durable and reliable, and that are manufactured using responsibly sourced materials and the efficient use of resources. While a circular approach requires upfront investments – for example, to set up take-back and recycling systems or lower our carbon footprint – it also spurs innovation, boosts competitiveness, and adds value to our brands.

Achieving our aims

At PMI, we are committed to understanding and managing the environmental and social impacts across our entire value chain, including the life cycles of our products. With respect to our smoke-free products, our 2025 eco-design and circularity ambitions, which extend to electronic devices, accessories, consumables, and packaging, are as follows:

providing collection and recovery access for the device and its consumables to all IQOS users;

reducing the carbon footprint of smoke-free products to below that of combustible cigarettes per user;

ensuring 100 percent of packaging materials are recyclable and 95 percent are from renewable sources; and

achieving eco-certification for all our electronic devices.

Our aims:

100%

Percentage of PMI smoke-free product users who have access to collection and recovery for devices and consumables by 2025

100%

Percentage of PMI’s smoke-free devices that have eco-design certification by 2025

Our journey to meet these goals relies on a systematic management approach in which sustainability is considered from the start of the product development process. The way we work is guided by the foundation principles of eco-design and circularity, which account for impacts relating to materials sourcing, product function and design, manufacturing, use, and end-of-life.

Our journey to meet these goals relies on a systematic management approach in which sustainability is considered from the start of the product development process.

These general principles informed our decision to integrate sustainable design into our corporate ambitions and ensure alignment with our R&D processes. Our designers and engineers increasingly are trained in eco-design by internal and third-party experts. Focusing on the major sustainability impacts of our products is particularly important as we deliver the technologically advanced products that are at the heart of our transition to a smoke-free future. In our operations, eco-design principles inform how we use life-cycle analysis (LCA) to assess the comparative carbon footprint of our products, from tobacco sourcing to end-of-life impacts. So far, we have analyzed IQOS, IQOS MESH, consumables (heated tobacco units), and packaging. Additionally, we are finalizing the results for the new generation of our Platform 4 product, the IQOS VEEV. This new version shows a continued improvement in CO2 footprint driven by efforts to reduce the overall product size, decreasing material usage. We will benchmark ourselves against peer companies that are also operationalizing eco-design.

Foundation principles of eco-design and circularity guiding our work

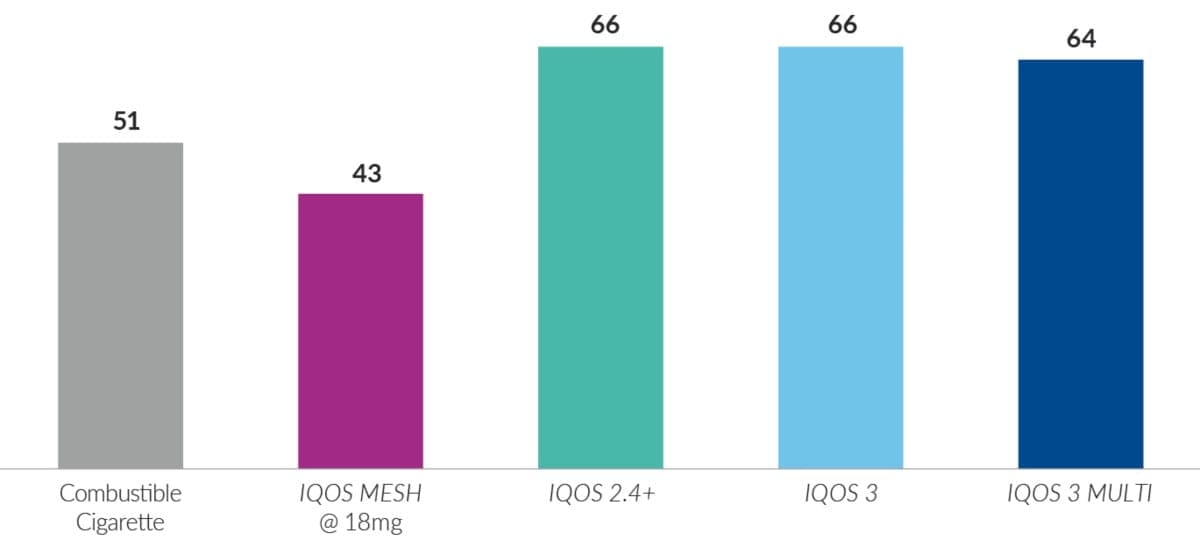

Life-cycle assessment - comparison of some PMI products (kgCO2e/2 years)

Note: This graphic is an internal assessment based on data compiled from three different LCAs, and assumes 20 heated tobacco units or combustible cigarettes per day. Scope includes materials, manufacturing, use, and end-of-life, but excludes logistics.

IQOS currently has a higher carbon footprint compared to combustible cigarettes due to several factors. Primarily, there is the addition of an electronic device, which involves new components and requires electricity to charge. This element accounts for 18 percent of the total carbon footprint of the IQOS 3 system. Additionally, the process to manufacture heated tobacco units is more energy intensive than cigarettes, due to the production of the cast leaf tobacco.

We are working to close the gap between combustible and smoke-free products through improved manufacturing processes, extending the usable life of our electronic devices, and working to decrease the total CO2 footprint through smart material selection and sustainable design practices. Over the past two years, we have reduced the overall CO2 impact of our smoke-free products through improvements in manufacturing processes and in our tobacco supply chain.

Focusing on the end-of-life of our devices, we adopted a centralized approach with the establishment of two recycling hubs in 2018 – one in Europe and the other in Asia. The benefits associated with such an approach include economies of scale, regional investment, illicit trade prevention, and quality enhancement (by identifying potential manufacturing and design improvements). In certain instances, owing to regulatory restrictions governing cross-border e-waste transportation, we may complement our centralized approach with more local solutions.

With regard to our consumables, for both our smoke-free and combustible products, we center our research efforts on testing biodegradable materials. We focus on materials that have the potential to perform similarly to or better than what we use currently and that may also reduce life-cycle CO2 emissions and have scientifically verified enhanced biodegradation properties in aquatic, soil, and marine conditions.

In packaging, more than 90 percent of our materials were paper and cardboard in 2019. The primary function of packaging is to contain and protect products from the point of manufacture to the retail store or end user, as well as to provide product information. Some of our smoke-free product consumables, such as MESH cartridges, require additional protection, which makes it challenging to ensure that packaging is made from fully recyclable materials. To address this challenge, we are committed to developing, by 2025, packaging solutions that minimize the use of plastics and aluminum and are fully recyclable.

Governance of eco-design and circularity is guided by our design and development teams and is fully embedded within our innovation process, including regular checkpoints with senior leadership. We are committed to evaluating sustainability characteristics and making design choices that will continually enhance the performance of all our products and packaging. Life-cycle analysis (LCA) and/or other relevant environmental assessments are performed prior to the launch of any new products, and results are presented in internal decision-making forums, in accordance with our sustainable design governance programs.

We are committed to evaluating sustainability characteristics and making design choices that will continually enhance the performance of all our products and packaging

Progress in 2019

Eco-design of smoke-free products

In 2019, we strengthened our efforts to integrate sustainability enhancements into product design. We have formalized our operational guidance on product design to incorporate eco-design principles. Prior to each launch, we compare product versions to ensure our newest iterations reflect these principles. This guidance supports decision-making and helps to integrate sustainability into our innovation process. We will continue to monitor the process using targets and performance indicators.

We promote five eco-design practices at PMI

1. Sustainable materials | Products should contain the correct quantities of materials, which are sustainably produced, and which have the lowest carbon footprint possible. This will deliver less waste during use and at the end-of-life. For instance, it means using recycled and sustainably sourced materials, produced in energy- and water-efficient processes. |

2. Minimize carbon footprint from energy and transport | Energy efficiency is a priority in PMI manufacturing operations. We are also already considering in the design process the energy consumption of the electronic devices that we sell to consumers. Furthermore, we aim to minimize the carbon footprint from transportation of raw materials and product distribution and reduce the weight of packaged products being transported. |

3. Lifetime optimization | PMI electronic devices and accessories should be designed to have an optimal lifetime with due regard for materials, electronics, and mechanical components available. Product design should include lasting aesthetics, products should be repairable, and packaging should be reusable or recyclable. |

4. Reuse, recycling, and recovery | We are increasingly adapting our design to use recycled materials and materials that are recyclable or biodegradable. Design should enable reuse and recycling by avoiding gluing or laminating, and new ways of doing business should embrace product take-back into a disassembly, separation, and recycling system. |

5. Social responsibility in production, use, and end-of-life | PMI devices and accessories should have no negative social impacts. PMI strives for positive social and ethical impacts upstream in the supply chain; for instance, by avoiding selecting and sourcing conflict minerals. Downstream, anti-littering behavior should be encouraged, and packaging should be informative about standards in production and how to recycle the device. |

The five eco-design practices shown in the table are currently applied to various degrees in PMI’s product innovation. Each generation of product we launch incorporates improvements in, for example, quality, functionality, ease of use, or robustness. A core group of employees – including our design and engineering teams – has been trained to our new standards, and we have set expectations and requirements for each new product iteration. These requirements are monitored throughout the design and production process, and performance is shared regularly with senior management in our Product and Consumer teams through the established development governance framework. Continued training and monitoring will occur in 2020 and beyond.

A core group of employees – including our design and engineering teams – has been trained to our new standards, and we have set expectations and requirements for each new product iteration.

Electronic devices and accessories

Regarding product innovation, we are pursuing improvements in areas such as durability, design for repair and/or disassembly, energy efficiency, and battery life. These characteristics will support our ambition to have all electronic devices certified to validated standards for eco-design by 2025. We will also be working toward the meaningful inclusion of recycled content in all devices by 2025.

As our business model is adjusting, circularity is steadily being applied. The user of a PMI device now has more opportunity to be part of the circular economy and to return a device that is broken or at the end of its life through a PMI take-back service.

We reported on our state-of-the-art reverse logistics hubs in our 2018 report. CIRCLE (Central Inspection and Recycling for a Closed Loop Economy) is a PMI service that provides centralized hubs that inspect, process, and separate materials from our electronic devices for recycling. In 2019, a third-party audit of our facility in Europe showed that we recycled at rates between 70 and 79 percent by weight based on device version; the remainder of materials went to energy recovery. Materials sent for energy recovery include some elements of the batteries and printed circuit board assemblies, which pose unique challenges.

In 2019, 39 percent of our IQOS market volume was covered by the CIRCLE takeback service, via retail stores or mail. IQOS users are always able to return an old device to specified locations; interested users should contact their local customer service channels for details. CIRCLE is a centralized service that ensures recycling is completed to the highest standards. To the extent possible, we are rolling out CIRCLE globally; however, it currently is not possible to implement the service in all markets due to legislative restrictions related to waste transport. In some markets where CIRCLE has not yet been implemented, IQOS users nonetheless can return their devices to specified locations. We aim to recycle these devices via local partners with similarly high standards of electronics recycling. We also participate in schemes that ensure a consumer can return devices to local e-waste collection centers in countries with such programs in place. In 2019, our CIRCLE hubs processed over 150 tons of end-of-life devices and materials destined for recycling or energy recovery.

The CIRCLE recycling hubs offer several benefits. The inspection of returned products allows us to improve quality by feeding back into our development process information related to possible manufacturing improvements or diagnosed defects. The recycling itself provides data that inform better design. The hubs contribute to our fight against illicit trade and counterfeiting (fewer product diversion opportunities) and bring benefits to the regional economies in which they are located. Through our CIRCLE hubs, we recover and recycle significantly more materials than if the devices were to follow traditional electronic waste streams in most markets. We continue to pursue reuse opportunities for these materials in both open- and closed-loop recycling systems.

In 2019, our CIRCLE hubs processed over 150 tons of end-of-life devices and materials destined for recycling or energy recovery

Consumables

As the design development process for electronic devices and accessories evolves, PMI is exploring how to minimize the environmental and social impacts of heated tobacco units – the sticks of tobacco that are inserted into an IQOS device. We are clear that there is a risk that heated tobacco units (HTUs) could be littered, but we have good indications, as mentioned below, that the littering rate for HTUs is lower than for cigarette butts.

In Italy, 80 percent of respondents to our survey claimed that they “never” or “rarely” dispose of the used HTUs on the ground when using IQOS outdoors. The corresponding proportion for our HTUs in Japan was 90 percent. In Italy, the data suggests that respondents dispose of used HTUs more properly compared to the claimed behaviors for cigarette butts at the time when the participants were not using IQOS (44 percent of participants claimed that they “never” or “rarely” dispose of cigarette butts on the ground, when they were smoking cigarettes outdoors). In Japan, the behavior of disposing cigarette butts on the ground was already infrequent (85 percent of the participants claimed that they “never” or “rarely” dispose of cigarette butts on the ground).1 These data points indicate that the new rituals introduced to legal-age smokers following their conversion to smoke-free products presents us with an opportunity to help consumers change former habits of cigarette butt littering.

In addition to these surveys, we have conducted actual counting surveys of littered HTUs as well as cigarette butts on the ground in Athens (see PMI’s Sustainability Report 2018). In this instance, the share of littered HTUs in proportion to cigarette butts came out at about half of the HTUs’ market share – indicating a significant lower littering propensity of HTUs compared to cigarettes.

In 2019, through extensive market research projects in some of our key markets, we continued to build our understanding of consumer behavior related to the disposal of used HTUs and consumers’ potential motivations and requirements for participating in a PMI-driven collection scheme. Collectively, these insights are shaping our understanding of how we can successfully deploy an effective and economically viable end-of-life collection service for our IQOS users in order to further reduce littering through our products.

Our long-term vision remains to recycle any waste that we collect while minimizing our CO2 footprint. In 2019, we continued to discuss with several waste management and recycling partners the potential second life that we could give to our recycled HTUs. Our exploration is primarily focused on the recycling of the cellulose acetate, the material our filters are made from. Our investigations to date show that the chemical properties of cellulose acetate enable the material to be upcycled into a variety of applications such as spinning of the fibers into fabrics or creation of pellets that can then be pressed/injection molded into a variety of hard goods. Though these results are promising, the recycling of cellulose acetate – unlike recycling for many metals or plastics – is not a widely available and developed waste stream across the globe that we can leverage.

We will continue in 2020 to work with partners to evaluate innovative solutions that may enable us to bring our long-term vision of full circularity of our consumables to life.

In addition to developing services to reduce the end-of-life impact of our products, our innovation and design teams are also exploring low carbon, recyclable, and biodegradable options for filters and cartridges. We are committed to significant investment into continued research on the biodegradability of filters, and we are working toward a viable solution that meets strict international standards2, satisfies market requirements, and works with high volume manufacturing.

We will continue in 2020 to work with partners to evaluate innovative solutions that may enable us to bring our long-term vision of full circularity of our consumables to life

Packaging

PMI has a history of successful packaging innovation, and packaging is an important aspect of sustainable design. Our packaging is made primarily from paper and board, renewable materials that can be recycled and that biodegrade in the environment. Sometimes these sorts of materials may come from supply chains exposed to significant risks of deforestation and biodiversity loss. We are committed to sourcing board and paper from traceable, sustainable, and legal sources, and we work with our suppliers to achieve full traceability through our Zero Deforestation program.

Plastic packaging poses a risk to the environment if it is discarded improperly, and we still have less than 10 percent of plastics-containing materials used in our portfolio, e.g. for wrapping films and pouches. To address this risk, we are testing potential alternatives to plastic packaging. The development process involves the use of recyclable cellulose materials meeting product protection requirements.

Besides plastics, one of our goals as we work toward fully recyclable packaging is to replace the non-recyclable aluminum liners used in some cigarette and HTU packets with recyclable alternatives by the end of 2022. In addition, for our combustible products packaging, we have established a program to reduce the weight of packaging by 15 percent over five years by optimizing material specifications and avoiding over packaging where possible without impacting product protection and package quality.

Next steps

We will continue the systematic implementation of our sustainable design principles throughout our development process. This will include a continuation of the internal training undertaken in 2019 to increase awareness and ensure uptake of our programs across PMI. This new design program will be benchmarked against leading companies to determine whether any modifications are needed to ensure the highest standards.

We will also launch a program to identify the relevant certification schemes for our smoke-free product devices as part of our efforts to reach our 2025 target for all electronic devices. We developed our eco-design principles with an eye to existing certification schemes and so anticipate that our devices will achieve these standards.

Regarding take-back for devices and consumables, such as HTUs and e-vapor cartridges, we will continue to evaluate and expand our offerings, with additional pilot programs for consumables planned in 2020. Our objective is to establish best-in-class recycling process for VEEV cartridges. We are working with an external partner on the collection and disintegration of the cartridges, and are entering explorations with the main polymer manufacturer of VEEV cartridges on how to recycle the plastic parts into new cartridges, as the polymer itself is proprietary and no independent recycling options exist.

We will also implement additional initiatives to encourage end-of-life returns of our devices to ensure our consumers have full access to our high recycling standards for electronics.

Research will continue on device, accessory, consumable, and packaging design to identify new technologies and materials that could enhance the overall sustainability of our smoke-free product portfolio. Internal cross-functional teams are already hard at work establishing these innovation pipelines.

1 In a sample of 350 adult IQOS purchasers randomly selected from the existing consumer panel in Italy, and in a sample of 450 adult IQOS purchasers randomly selected from an existing online panel in Japan (see third attachment of report submitted to FDA).

2 For example, good filtration efficiency and consistency to ensure that consumers are not exposed to increased levels of HPHCs versus products made with cellulose acetate filters.

This online supplement to our integrated report should be read in conjunction with PMI’s Integrated Report 2019. The information and data presented in this online supplement cover the 2019 calendar year or reflect status at December 31, 2019, worldwide, unless otherwise indicated. Where not specified, data come from PMI estimates. See About this online supplement for more information. Aspirational targets and goals do not constitute financial projections, and achievement of future results is subject to risks, uncertainties and inaccurate assumptions, as outlined in our forward-looking and cautionary statements.