| INTEGRATED REPORT 2019 |

Why it is important to us and our stakeholders

Adequate waste management brings efficiencies allowing for better and more equitable use of resources. Improper disposal of waste has clear negative environmental and social impacts. It can lead to pollution and contamination of groundwater systems, damaging ecosystems and biodiversity. Furthermore, it can negatively affect the health and well-being of surrounding communities and lead to a loss in property value.

The resources we use at PMI to manufacture our products are valuable, so we aim to ensure they are used effectively, avoiding waste when possible. Waste minimization creates cost savings and means that fewer materials become by-products. It protects our license to operate by maintaining good relationships with neighboring communities and can help us create new partnerships with experts in this field. Where possible, we create value from by-products through recycling and energy production. Further, proper waste management is also key to preventing illicit trade owing to the risk of tobacco-processing by-products being diverted from the correct waste disposal process.

Achieving our aims

We are committed to reducing the waste generated in our operations and to identifying and applying the most sustainable waste treatment options available. All waste from a production site is managed, including waste from catering, rest areas, laboratories, and health care facilities. At PMI, we focus on the most valuable waste streams, such as tobacco by-products, paper, card, and cellulose acetate tow.

We are committed to achieving virtually zero waste to landfill across all PMI manufacturing operations by 2022. We aim to achieve this while complying with all relevant waste regulations and standards. All our manufacturing sites have annual waste targets that are supported by specific projects to ensure their delivery.

We apply a “zero waste” philosophy, but we acknowledge that even the most efficient systems inevitably involve a small amount of landfill; for instance, waste-to-energy ash residue, waste legally mandated for landfill, and greywater sludge.

Our standard on the management of hazardous materials guides specific treatment options for hazardous waste. We dispose of unused flavors under specific national waste treatment protocols. In addition, we are aligned to the Basel Convention, ensuring no transshipment of hazardous waste occurs in our operations.

Governance of how we deliver waste management relies on clear internal roles and accountability. Our central manufacturing sustainability department defines the waste management framework for delivery by local teams. We use an internal waste management standard to guide both how we manage waste in all PMI manufacturing centers, laboratories, and warehouses and how we organize waste contractors. Facility managers are responsible for assessing all types of waste arising on a given site, as well as for the security arrangements and legal requirements for each type of waste. Further, they control how waste is stored, handled, transported, segregated, labeled, and treated by waste contractors. A site-level waste management program accounts for ecological, social, and economic impacts and governs the development and implementation of relevant waste initiatives. A waste hierarchy – minimize, reuse, recycle, recover, incinerate/landfill – is applied under each plan. Potential waste impacts such as spills are included in our corporate integrated risk assessment and subject to regular review.

Progress in 2019

In 2019, half of our factories had less than 1 percent waste to landfill. Total waste generated has decreased 2 percent compared with 2018 (to 131,104 tons, of which 1 percent was hazardous).

We have certified 98 percent of our factories to the ISO 14001 environmental management system standard, which includes waste management. An internal review of our factories in 2019 showed that we safely dispose of regulated waste wherever we operate around the world. Naturally, we are seeing varying levels of progress toward our current goal of less than 1 percent to landfill across our manufacturing sites; some sites, for example, need improved waste segregation, others require capital investment in equipment or transport, and others face the challenge of halting the criminal diversion of tobacco by-products that are to be disposed of.

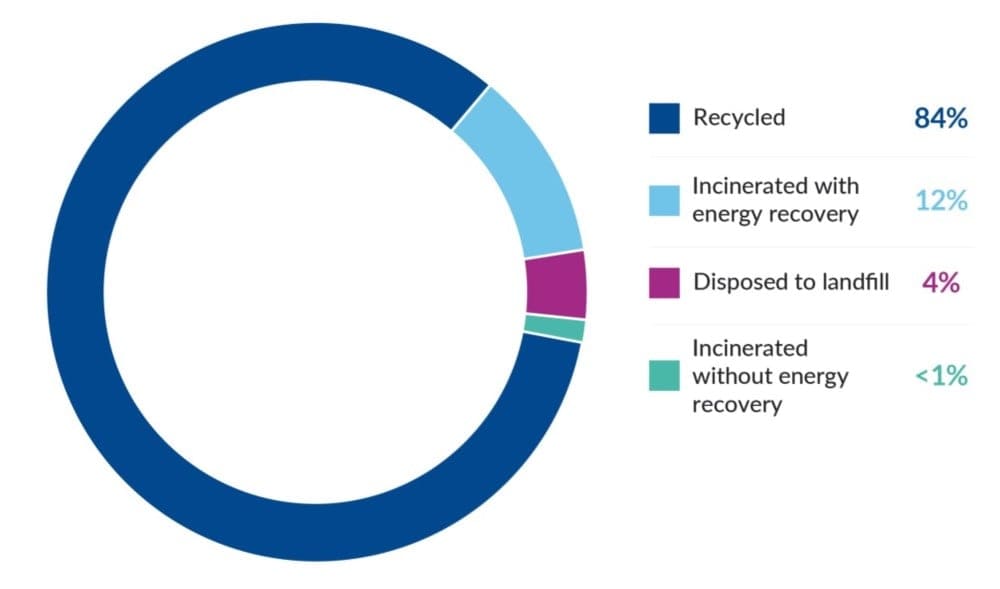

Disposal of waste generated in 2019

We also look beyond compliance and objectives to identify opportunities. In Turkey, for example, we make use of acetate tow by-products. A local construction materials producer uses it as a filler in cement blocks and other products. Such industrial symbiosis is increasing in the cement industry.

Working with our suppliers is key to achieving our commitment to waste reduction. Through collaboration, we can minimize the amount of materials entering our factories. In our offices, we aim to adopt circular economy principles where possible. Our employees play a key role in helping us use less and to reuse and recycle materials wherever we can. An effective way to reduce waste is to cut down on single-use plastic. For example, our affiliates in Indonesia, Italy, Germany, and Turkey have already taken steps to remove single-use plastic cups with mugs and water bottles in their offices.

Next steps

We continue to manage waste in line with regulations and our own standards and plans. We continue our focus on achieving zero waste in our operations and are planning to test new technologies such as incineration with energy recovery using pyrolysis at certain sites (read the example of our Swiss-based factory).

Our approach to materials, packaging, waste management, and electronic product stewardship increasingly aligns with the concept of the circular economy. We expect to report in the future on innovations in the areas of material substitution, manufacturing process efficiencies, and industrial partnerships on waste reduction.

This online supplement to our integrated report should be read in conjunction with PMI’s Integrated Report 2019. The information and data presented in this online supplement cover the 2019 calendar year or reflect status at December 31, 2019, worldwide, unless otherwise indicated. Where not specified, data come from PMI estimates. See About this online supplement for more information. Aspirational targets and goals do not constitute financial projections, and achievement of future results is subject to risks, uncertainties and inaccurate assumptions, as outlined in our forward-looking and cautionary statements.